HOT DIP GALVANIZING

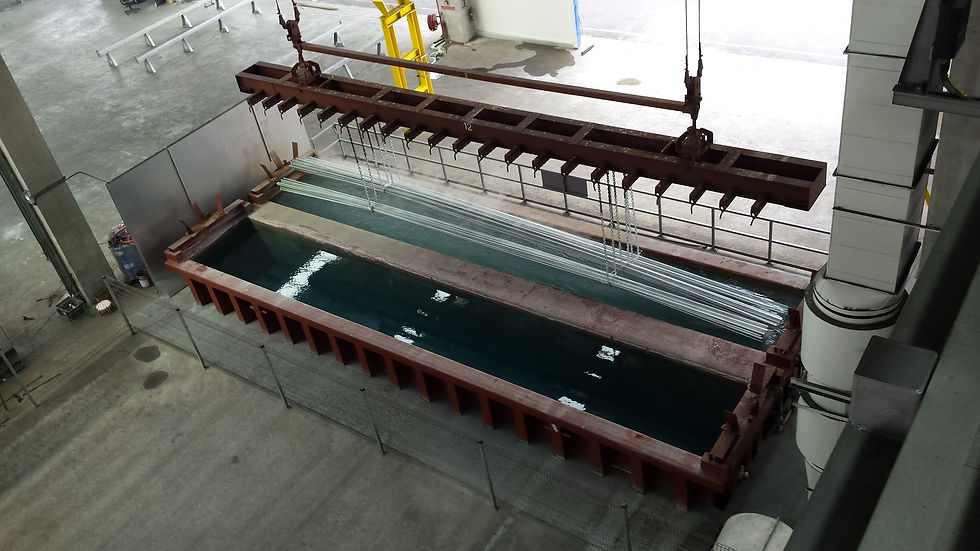

FULLY AUTOMATED HOT DIP GALVANIZING PLANT

In 2016, we invested in a factory which uses the best technology in the world. Built by crane experts from Europe, our hot-dip galvanizing plant utilizes state-of-the-art technology, and is the first of its kind in South East Asia.

Creating a safer working condition for our employees and a greener environment, Progress is committed to delivering superior corrosion-resistant zinc coating that will last.

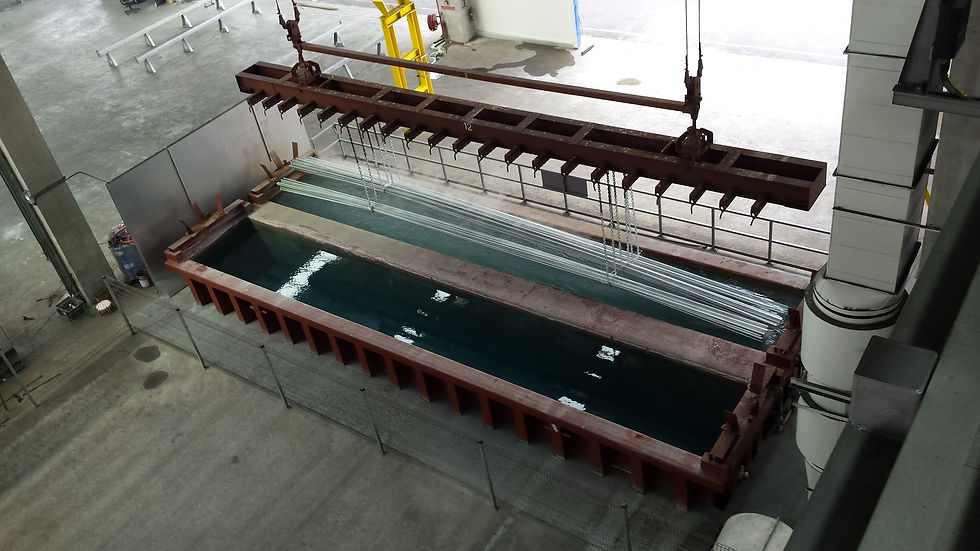

MANUAL HOT DIP GALVANIZING LINE

In 2024, the company has enhanced its operational capacity by integrating an additional hot dip galvanizing line specifically designed to accommodate larger materials and increased production volumes.

The newly installed manual galvanizing line features an open-concept design, facilitating seamless passage of larger materials without hindrance. This design not only optimizes operational efficiency but also underscores the company's commitment to environmental sustainability.

Equipped with the state-of-the-art scrubber and dust filter systems, the line effectively eliminates acidic fumes and smoke, thereby fostering a safe and eco-friendly workplace environment for our employees.

AUTOMATIC CENTRIFUGAL GALVANIZING

In 2014, the company invested in an automated spinning line for galvanizing smaller parts. Fabricated and installed by a Dutch company, our spinning plant is the only of its kind in Singapore. Centrifugal galvanizing guarantees uniform coating on small parts, such as threaded bolts, with no additional touch up required due to wire marking or excess zinc spikes. This enables high quality hot dip galvanizing of small parts, and in particular threaded parts.

A SPECIAL VIDEO, JUST FOR YOU

For more information on galvanizing in Progress, have a look at our company's special video presentation on this page!